Jig and Fixtures are devices or equipment designed to assist in the process of working on the same part of a component in bulk, thereby reducing the effort required to work on the same part and increasing the precision of the final product, as well as improving production efficiency.

If a product or object is to be mass-produced in identical shapes and sizes, it generally uses devices or tools to hold and position the material to be processed (raw material) so that manufacturing processes can be performed repeatedly. The tools used may be jigs and fixtures, or even used together

Jig

Jig is a device or tool used to guide a chisel or cutting tool according to the desired position, shape, and cutting size. Jig functions to direct the chisel to the appropriate position based on reference images, specifications, and machine operation.

By using a jig tool, production speed can be significantly increased in machining processes because there is no need to repeatedly adjust placement, alignment, and measurements.

Fixtures

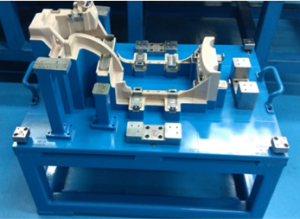

Fixture is a device or tool that functions as a holder, support, and positioning tool for workpieces according to the machining position, so that the workpiece does not shift or change position during machining processes.

In other words, the use of fixtures aims to lock the position or placement of the workpiece to prevent position changes that may cause product failure during the production process.

Advantages of Using Jigs and Fixtures in the Manufacturing Process

The use of jig and fixture tools in the manufacturing process can help improve production performance, increase efficiency in terms of time, and enhance precision. Additionally, here are some advantages of using Jigs and Fixtures in machining and manufacturing processes:

- Significant increase in production rate, especially for items produced on a mass scale.

- Elimination of the need to measure, punch, position, align, and set up for each workpiece, thus reducing cycle and setup times.

- Consistent product quality with high accuracy.

- Reduction of unnecessary costs and minimization of additional costs due to manufacturing errors.

- Inspection and quality control processes can be efficiently conducted.

- Because the cutting position and workpiece are already set, the production process can be carried out by semi-skilled workers.

- Components with complex shapes can be easily worked on.

Manufacturing processes are carried out with simpler assembly operations, reducing non-productive hours and thereby reducing production costs from the labor perspective.